1. Structures and Working Principles of Three Types of Reducers

1.1 RV Reducer – A Robust Torque Transmission Solution

Structure & Principle

The RV reducer (Rotary Vector Reducer) is a precision device that combines a planetary gear system in its first stage with a cycloidal pin-wheel mechanism in its second stage. The input shaft drives the planetary gears, which rotate around a central sun gear and simultaneously drive the cycloidal pin-wheel in a reverse low-speed motion. This innovative design achieves a high reduction ratio within a compact space while maintaining rigidity and precision-qualities that are essential for handling high loads and delivering substantial torque.

Typical Applications

Commonly used in load-bearing joints such as the robot's waist and legs.

Provides robust and stable power support for heavy-duty tasks like carrying loads, running, or jumping.

1.2 Harmonic Drive – Precision Transmission Through Flexible Deformation

Structure & Principle

The harmonic drive consists of three main components: a wave generator, a flexspline (flexible gear), and a circular spline (rigid gear). As the wave generator (typically elliptical or polygonal) rotates within the flexspline, it forces the flexspline to deform elastically. This deformation causes the long axes of the flexspline's teeth to engage fully with the circular spline while the short axes disengage. The resulting cyclical process of engagement and disengagement yields a high reduction ratio with exceptional precision and almost zero backlash.

Typical Applications

Ideal for parts requiring high precision, such as the robot's arms and wrists.

Suitable for fine operations like grasping small components or precision assembly, where minimal error is crucial.

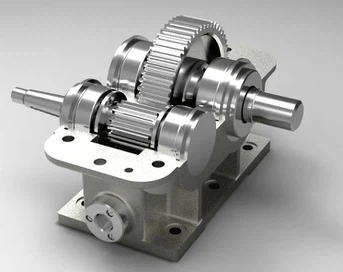

1.3 Planetary Reducer – A Compact and Efficient Design

Structure & Principle

Based on the planetary gear system, the planetary reducer comprises a sun gear, planet gears, a planet carrier, and an outer ring gear. When the input shaft rotates the sun gear, the planet gears revolve around it while also rotating on their own axes and engaging with the outer ring gear. By carefully adjusting the gear tooth counts, the desired reduction ratio is achieved. This design is compact, efficient, and generally cost-effective.

Typical Applications

Often used in rotational joints or parts with moderate torque demands where high transmission efficiency is needed.

Employed in the design of robot legs or head rotational joints, where both stability and efficiency are important.

2. Performance Characteristics

Torque and Load Capacity

RV Reducer: Its dual-stage transmission enables high torque output and robust load capacity, making it ideal for major load-bearing components.

Harmonic Drive: Although compact, its multi-tooth engagement design maintains high precision under lighter loads, focusing on delicate motion control.

Planetary Reducer: With evenly distributed load across multiple planet gears, it offers efficient transmission for moderate torque while ensuring stable performance.

Precision and Stability

Harmonic Drive: Thanks to its flexible deformation and multi-point engagement, it achieves extremely low transmission error and near-zero backlash, perfect for high-precision positioning.

RV Reducer: Its rigid structure helps maintain consistent precision over prolonged high-load operation, suited for industrial environments.

Planetary Reducer: While its precision is slightly less than that of a harmonic drive, its stable multi-point transmission meets most precision requirements effectively.

Size and Weight

Harmonic Drive: Its compact size and light weight-often reducing volume and mass by up to two-thirds and one-half respectively-make it ideal for applications with strict space and weight constraints.

RV Reducer: Designed to handle high loads, it is naturally larger and heavier; however, this is an acceptable trade-off in scenarios demanding high torque.

Planetary Reducer: Its compact design and high power density strike a balance between space, weight, and transmission efficiency, fitting well into cost-sensitive and space-limited applications.

3. Application Layout in Robotic Joints

3.1 Load-Bearing Joints

In areas such as the robot's waist and legs-where the joints must support significant weight-the RV reducer is often the preferred choice. Its exceptional torque and load-bearing capacity ensure that the robot remains stable and balanced even during dynamic actions like running or jumping.

3.2 Precision Operation Components

For parts like the arms and wrists, which require meticulous control and delicate handling, the harmonic drive excels with its high precision and almost zero backlash. It enables the robot to perform tasks such as grasping or assembly with remarkable finesse.

3.3 Rotational and Flexible Joints

The planetary reducer is frequently used in rotational joints or areas with moderate torque requirements. Its efficient power transmission and compact design support the smooth rotation of components like the robot's head or certain leg joints, contributing to overall agile movement.

Conclusion and Outlook

As humanoid robotics technology advances, the design and manufacturing of reducers continue to evolve. Each type offers unique strengths:

RV Reducers provide the robust support needed for heavy load-bearing tasks.

Harmonic Drives deliver unparalleled precision in applications requiring fine control.

Planetary Reducers balance efficiency and compactness for cost-effective designs.

With ongoing innovations in materials, structural design, and manufacturing processes, the future holds promising breakthroughs for reducers-pushing the boundaries of high precision, high torque, and lightweight performance. These advancements will further empower robotic technology, paving the way for smarter, more capable machines.